core competitiveness

-

-

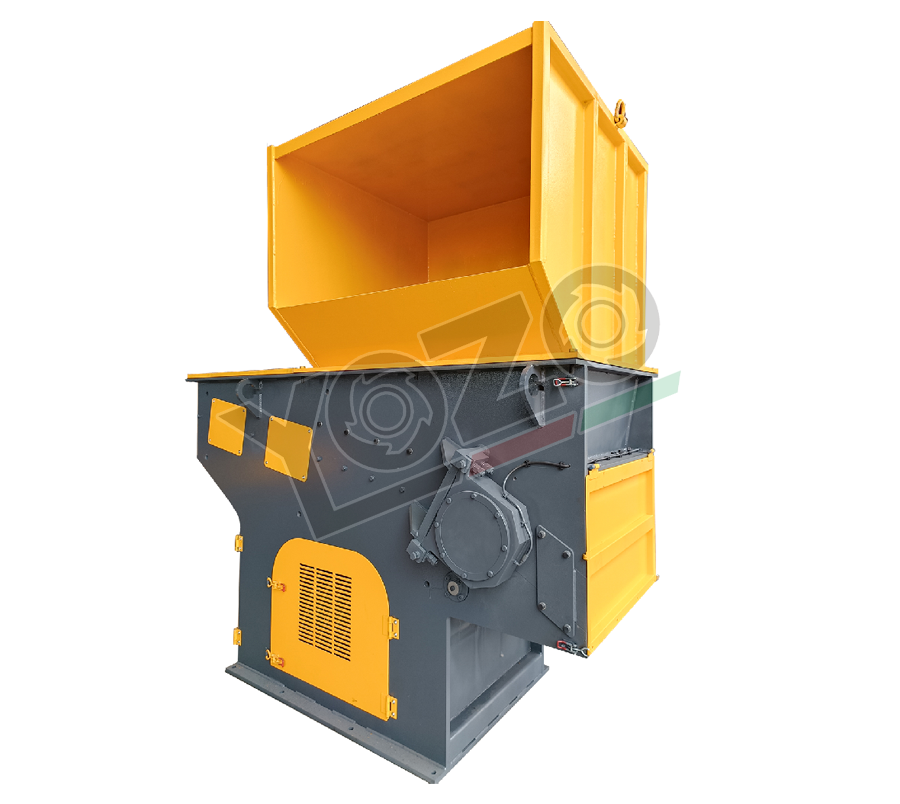

Shredder manufacturer

Self owned brand, source manufacturing

-

-

Core technical talents

Scientific development, worry free and cost-effective

-

-

local service

Thoughtful service, timely response

-

-

Flexible cooperation mode

Cost-effective Multiple

-

-

Multiple project cases

Multiple scenarios, practical implementation

CLASSIFICATION

-

-

ABOUT YUZHUOCompany Profile

Anhui Yuzhuo Machinery Co., Ltd. is a modern factory located in the High tech Industrial Park of Bowang District, Ma'anshan City, integrating design, research and development, production, and sales. ···

MORE >

More information about shredder equipment

- 08.282024

How to solve the problem of vibration in metal shredder?

A metal shredder is a specialized mechanical equipment used to process metals. The waste plastics processed by the metal shredder not only improve resource utilization, but also reduce raw material waste and improve our living environment. However, as a mechanical equipment, it is inevitable to encounter various malfunctions in daily work. For example, if the metal shredder vibrates during production, how should we solve them? Below, the editor will analyze and answer for everyone. 1、 If it is caused by the rotor of the metal shredder not being concentric, we can move the position of the motor to the left or right, or add a pad under the motor foot to adjust the concentricity of the two rotors. 2、 When the vibration frequency of the metal shredder is high, it may also be due to the lack of concentricity between the coupling and the rotor, or uneven quality of the flat hammer pieces inside the rotor. At this time, corresponding methods should be adopted according to different types of couplings. 3、 The vibration of the metal shredder may also be due to the equipment itself not reaching balance. This may be because the fixation of the metal shredder is not firm enough. This problem can be easily solved by ensuring the firmness of the metal shredder. The anchor bolts should be tightened to avoid vibration of the metal shredder. In short, if there is any vibration during the production process of the metal shredder, it must be stopped immediately for inspection, and the cause must be identified and measures taken to deal with it.

- 08.282024

The key equipment in the garbage disposal and recycling industry - shredder

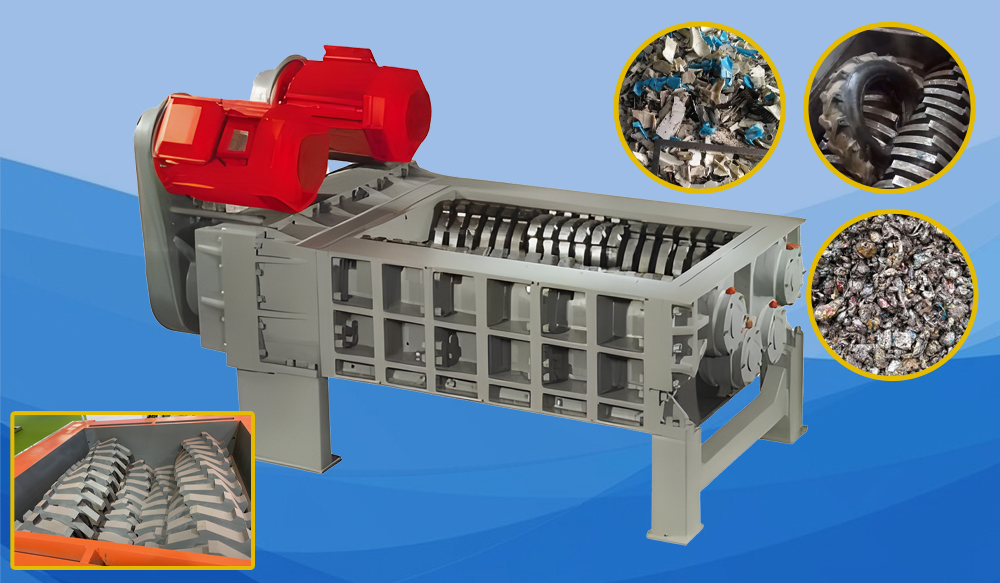

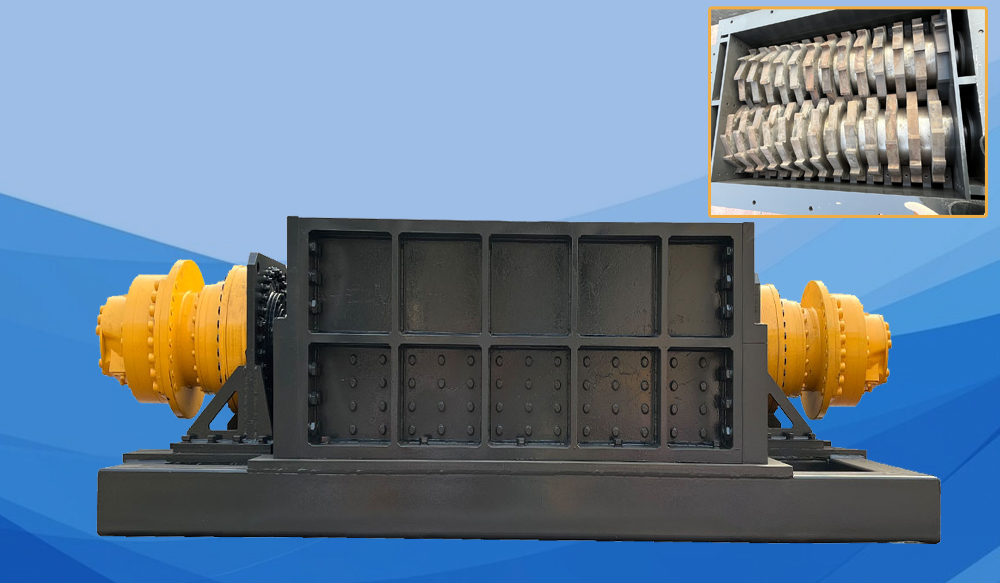

The shredder is one of the key equipment in the garbage disposal and recycling industry. It crushes various waste materials such as paper, plastic, and electronic waste into small pieces or fibers through strong mechanical force for further classification and recycling. In modern cities, the types and quantities of garbage are constantly increasing, and traditional landfill and incineration methods are no longer able to meet the requirements of sustainable development. Therefore, shredders play a crucial role in the garbage disposal process. It not only improves the efficiency of garbage disposal, but also reduces environmental pollution. There are various types of shredders, covering a wide range from simple household small shredders to large industrial grade equipment. Among them, large-scale shredders have been widely used in garbage treatment plants and recycling centers, which can efficiently process large amounts of industrial waste and urban household waste. As an excellent manufacturer of waste material recycling equipment, Wesken's shredder products have demonstrated significant advantages in the field of waste treatment and recycling due to their superior performance. In order to meet the needs of different material processing, the shredder is equipped with a variety of blades and screens. The material and shape of the blade are carefully designed to efficiently crush materials of various hardness and toughness. The DL large double axis shredder carefully developed by Wesken Company has been widely used in the recycling and treatment of industrial waste, urban solid waste, and other comprehensive waste. The blade body of the shredder is made of high-strength 42CrMo alloy steel, ensuring efficient high-power shredding ability, and the blade thickness can be selected according to demand. In addition, its detachable blade design greatly reduces the time required for blade replacement. In addition to continuous improvement of hardware equipment, the intelligence level of shredders is also steadily improving. Modern shredders are equipped with advanced control systems that can monitor the real-time operation status of the equipment and automatically adjust the crushing parameters to ensure that the equipment always operates in an ideal state. With the continuous development of technology, shredders are expected to become more efficient, environmentally friendly, and intelligent, providing solid support for the resource utilization, reduction, and harmless treatment of garbage. And Wesken Company will also be committed to continuous technological innovation and application expansion, continuously upgrading shredder technology to more effectively protect the environment and help achieve the grand goal of sustainable development.

- 08.282024

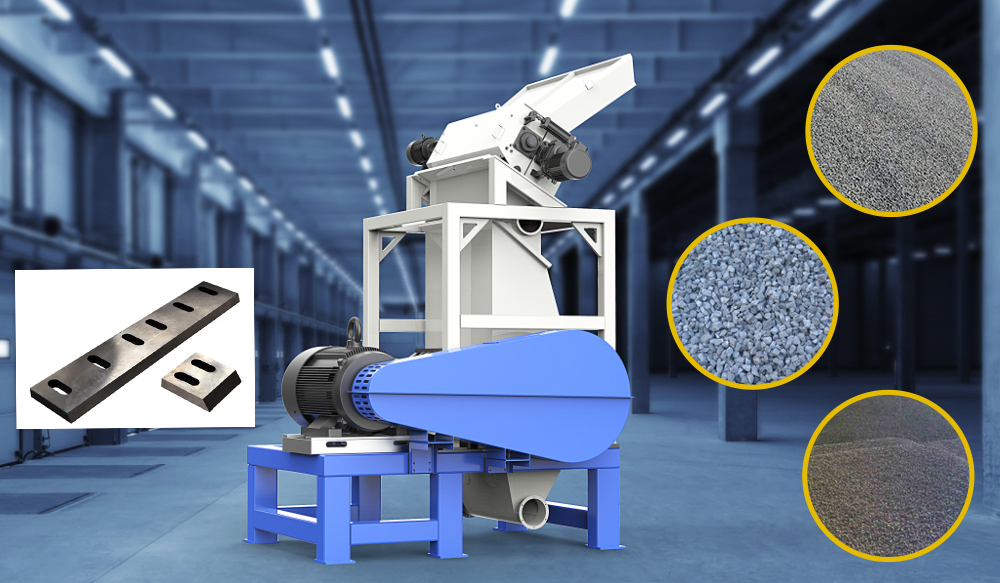

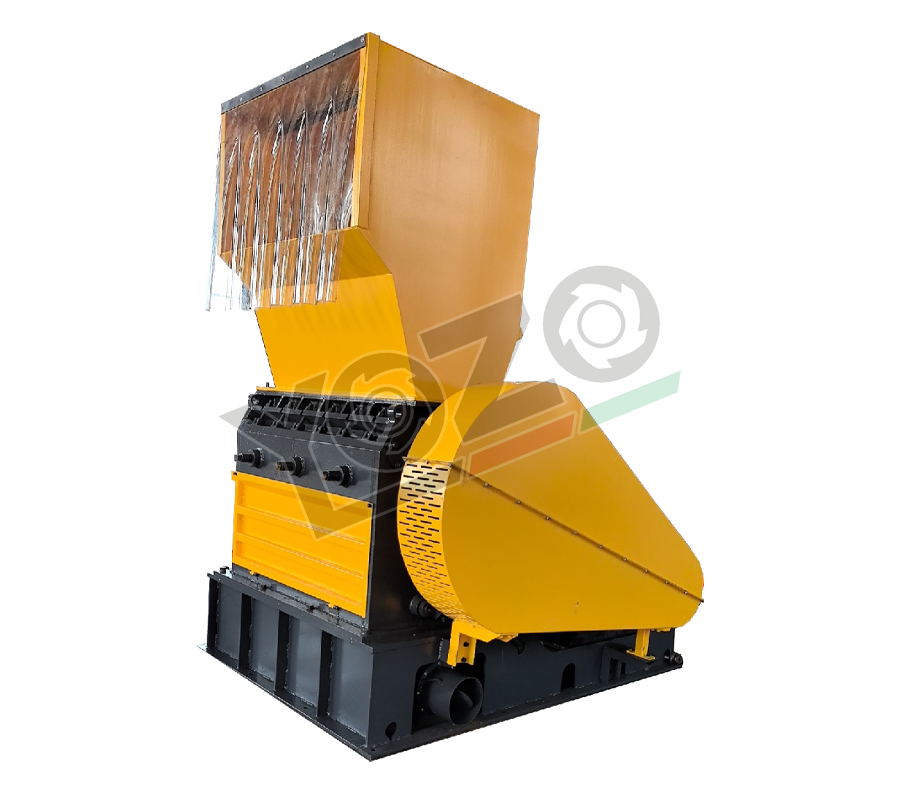

How to handle and utilize waste tires with a shredder

The shredder plays an important role in processing waste tires, and its working principle and application range are very wide. After being processed by a shredder, waste tires can be turned into treasure and resources can be reused. Firstly, the shredder tears the waste tires into smaller pieces through strong shear force. These fragments can then be further processed for various purposes. A common application is to use shredded tire fragments for the production of rubber particles. These rubber particles can be used to lay the ground for sports fields, children's playgrounds, and even for road construction. Through this method, waste tires are effectively reused, reducing environmental pollution. In addition, shredded tire fragments can also be used to manufacture recycled rubber. Recycled rubber can replace some natural rubber and be used to produce new tires or other rubber products. This not only saves resources, but also reduces production costs. The DL dual axis shredder developed by Wesken Environmental Protection is a large-scale equipment capable of processing various solid waste materials. The size of its broken particles can be set by adjusting the thickness of the blade. The blade body of the shredder is made of high alloy CrMo material, which not only enhances its shredding ability but also ensures durability under high-power operation. It is worth mentioning that the DL dual axis shredder performs excellently in processing waste tires, whether it is producing rubber particles or producing recycled rubber, it appears to be effortless. In addition, the device is equipped with two independent motor drives and a high safety factor gearbox, which can generate extremely high torque. In addition to the above applications, shredded tire fragments can also be used to manufacture rubber bricks. These rubber bricks can be used to lay sidewalks, parking lots, and docks, and have good anti slip and shock absorption properties. At the same time, they also have high durability and anti-aging performance, long service life and low maintenance costs. The M-series heavy-duty single axis shredder developed by Wesken Environmental Protection offers two options: circular and hexagonal mesh screens for precise control of material size. The waste tires that have been shredded can be effectively screened using the M-series single axis shredder to meet the application needs of various fields. In addition, the shredder is equipped with a hydraulic screen holder, making screen replacement exceptionally easy. In the field of environmental protection, the application of shredders is not limited to the treatment of waste tires. It can also be used to process other waste rubber products, such as waste shoe soles, rubber hoses, etc. Through the processing of shredders, these waste rubber products can also be transformed into various valuable resources, achieving the recycling of resources. The shredder has a wide range of application prospects in processing waste tires. Through continuous technological innovation and improvement, shredders can process waste tires more efficiently and environmentally friendly, making important contributions to resource reuse and environmental protection.